Good news:

Pressure readings of both sensors show nearly same value, therefore I would rate them to be ok. Highly unlikely that both fail.

Bad news:

in second video CEL is already on, I assume it is P0101.

According to description, fault reaction would be:

Fuel adaptation zeroed. Intake pressure and intake air temperature is used as substitute values for the mass air flow sensor. This value is used for instance for fuel calculation instead of the value from the mass air flow sensor, which is considered unreliable.

I assume, AMUL should be reset to 0, but it shows a value different from 0. (But I do not know, if they just reset it to zero internally and still keep the value shown, never had and P0101 before).

If fault reaction is already used, we cannot trust MAIR anymore.

(From measurement, MAIR seems to be too high compared to inlet pressure, indicating a leakage. But I do not know if MAIR is still from MAF sensor or already replacement value).

Therefore:

1. Was CEL triggered by P0101, FCOD should state 257?

2. There are no other errors present? NERR = 1?

3. Could you do some testing without CEL already on, you said, it takes 50-100km, therefore reset before should grant some time for testing. Full load and medium load with boost at 300-500mbar might also help

4. I would still pressure test the hole system:

- Remove rubber pipe between MAF and cobra, cover cobra with rubber glove, put some old piece of fabric over the glove and fix everything with a clamp or zip tie. (Or find fitting plug at home depot store, there is one robust rubber plug available which fits cobra pipe, at least I found one here).

- Remove oil filler cap (just to prevent leakage blowing up the crankcase and pressing out oil or sealings)

- Either remove bolt on top of cobra and plug thread, but it is not a normal thread (I think M16 x 1.5, do not use normal screw, it will ruin thread). Or remove tube at end of this pipe and plug the pipe there.

- Disconnect rubber line from APC valve to cobra, marked with R, at APC valve and use this connection to inject compressed air with air gun. Reduce pressure to 0.5 bar at compressor before, do not blow up the engine with 10 bar.

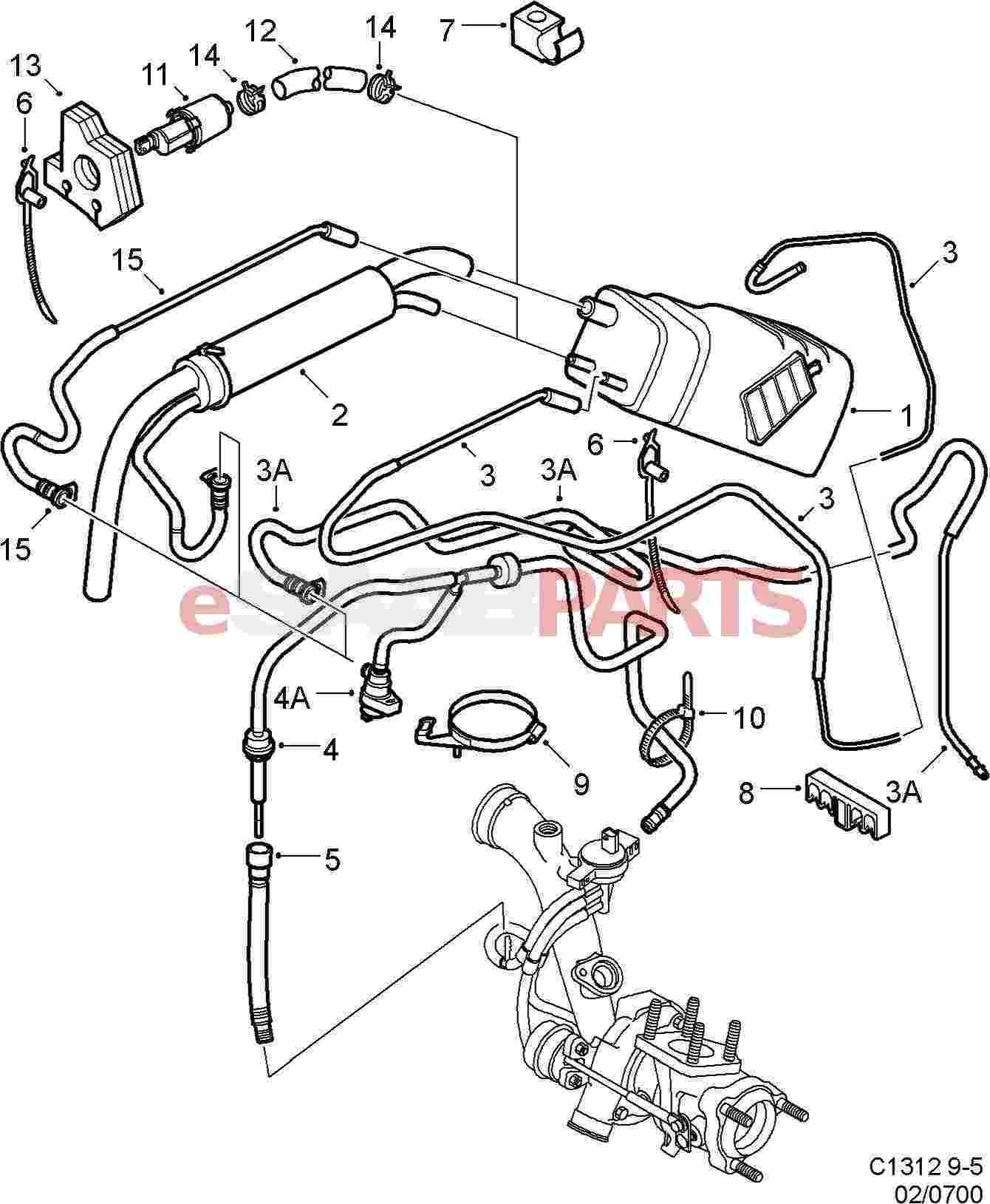

- Remove the evap valve, see here at 12.

Description above is similar to described testing in WIS.

Important:

Have you checked the check valve from throttle body to evap valve? very often they are shot. Remove tube at the back of throttle body and try to blow air in. It should be closed. If not, two things happen: you loose boost pressure and you increase backpressure for APC valve, as this line is connected to to R line, therefore APC is not working properly.