A few months ago I rehabbed my 2005 Jeep Liberty CRD, and part of that adventure was eliminating the crank-driven mechanical fan and replacing it with a gigantic 600w electric fan from a BMW. It was a fun adventure... I was out of touch on exactly how amazing modern radiator fans are!

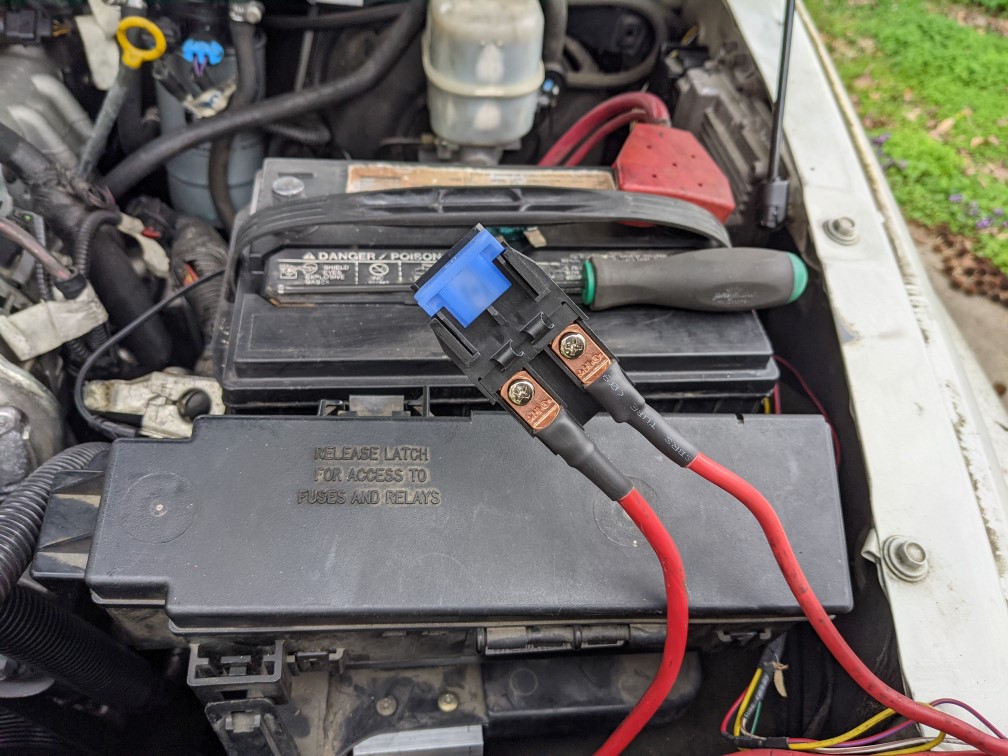

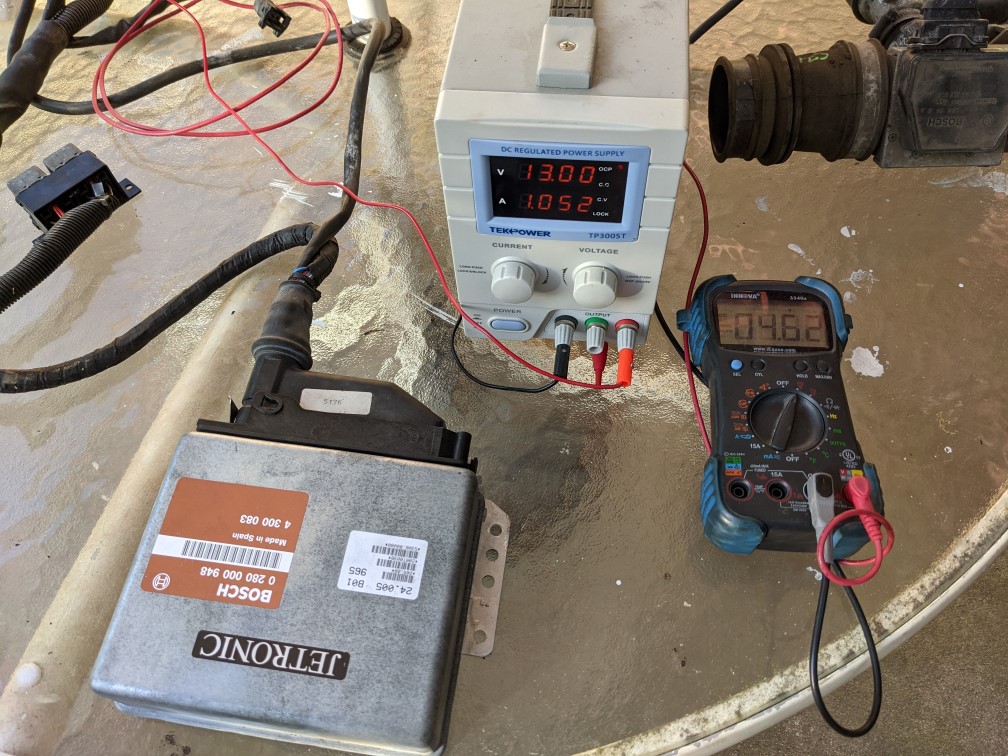

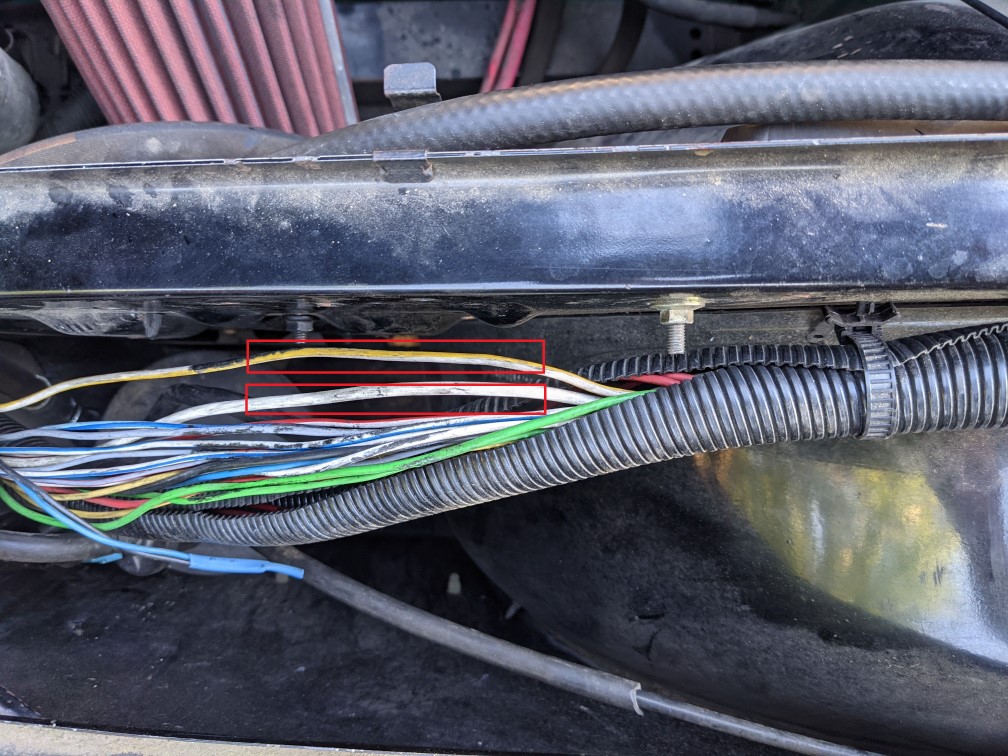

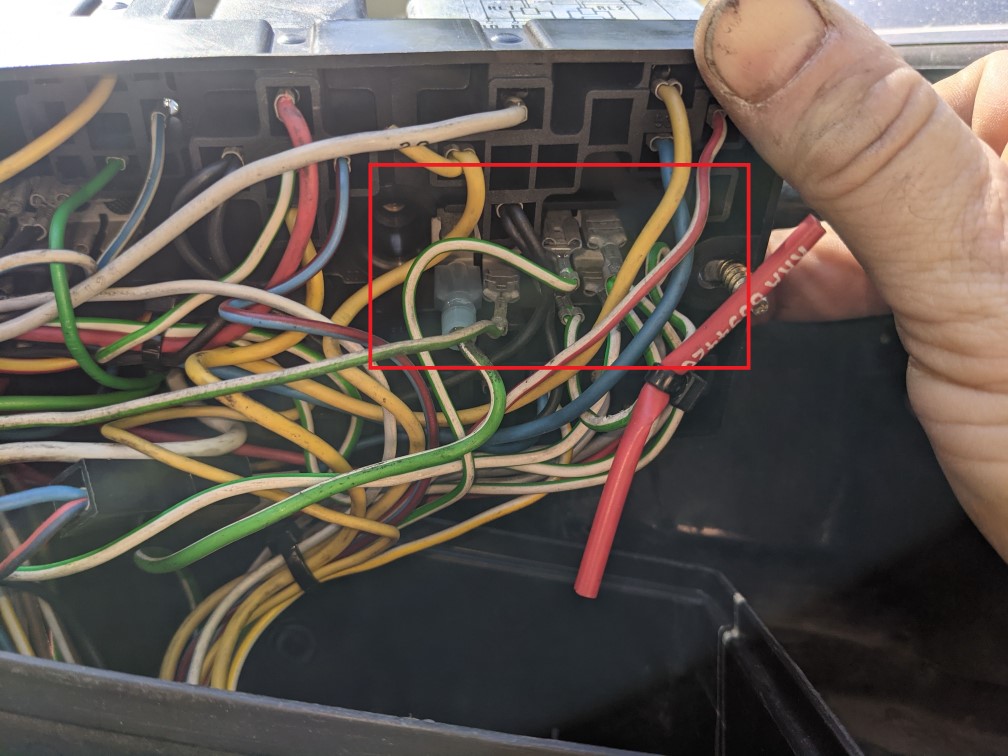

It's been a rip-roaring success, so I'm going to replicate pieces of that project on a c900. Here's most of the parts:

![Image]()

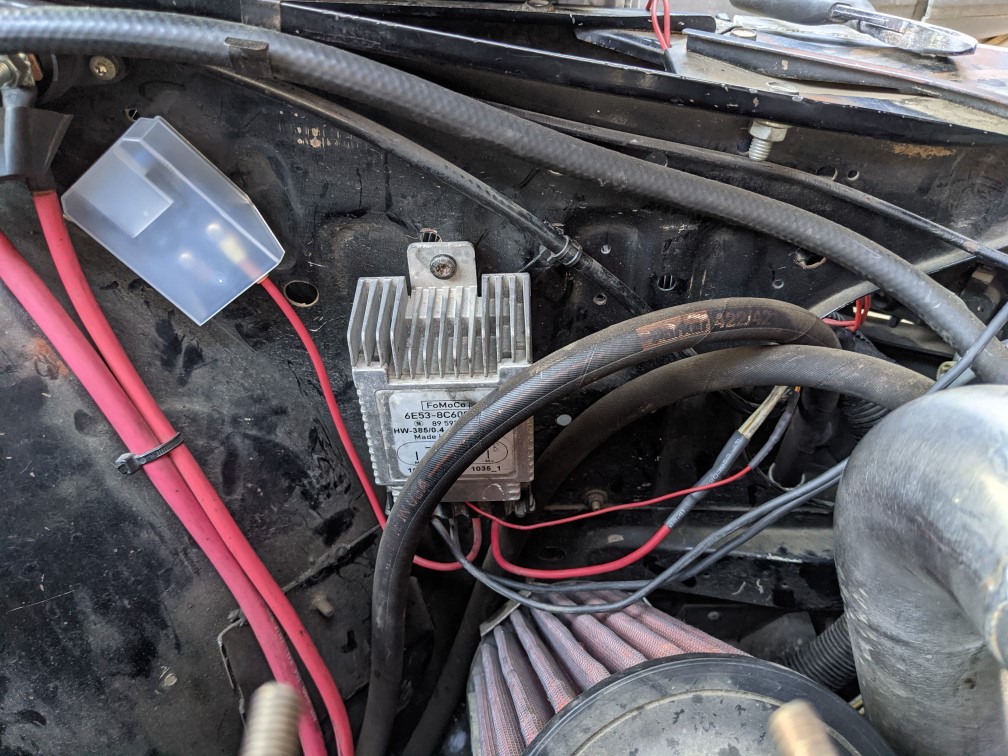

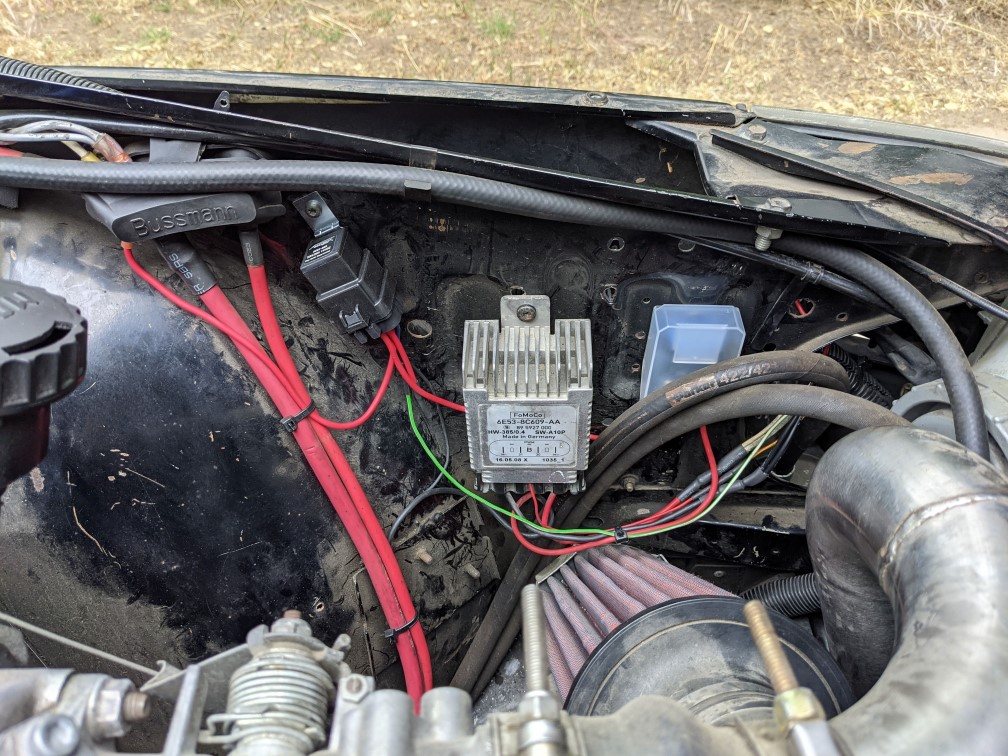

The key bit in that photo is the silver Ford fan controller - part number 6E53-8C609-AA. It's found on later 1st gen Fusions. It's also GM part number 10377609 found on C6 Corvettes. It probably shows up other places, too.

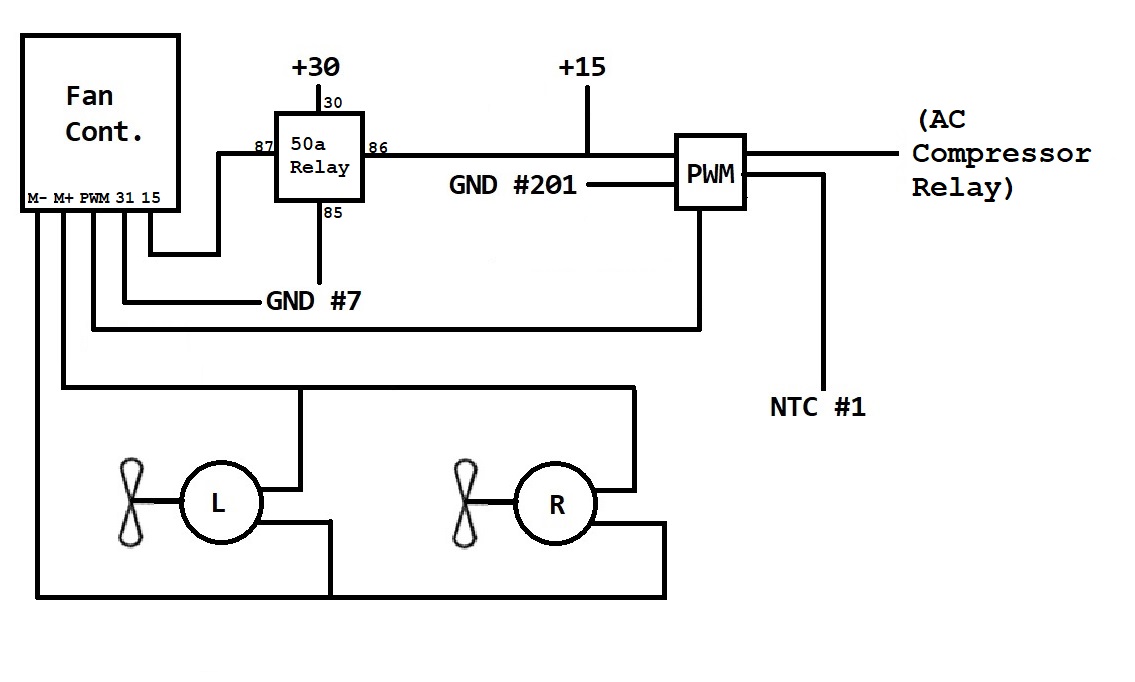

This magic box takes in battery voltage and a PWM signal, and then uses that to modulate power to a DC fan. In concept, it's like the 2-speed fan on the 9000/9-3/9-5 BUT rather than using a resistor to get two speeds it has an infinite number of speeds. (Probably, that's not true - it's probably stepped and just has "a lot" of speeds).

The benefit of using PWM is two-fold: We eliminate high inrush current associated with accelerating a fan from stopped to full speed, which on a c900 should reduce that annoying sag in idle speed when the fans kick in. Also, rather that wait until the engine is "too hot" and then race to cool it down, we can run a fan at low speed relatively early to take the edge off, and accelerate the fan as necessary. In theory, this should result in more stable engine temperatures and reduced load on the electrical system (maybe increase fuel economy a smidge).

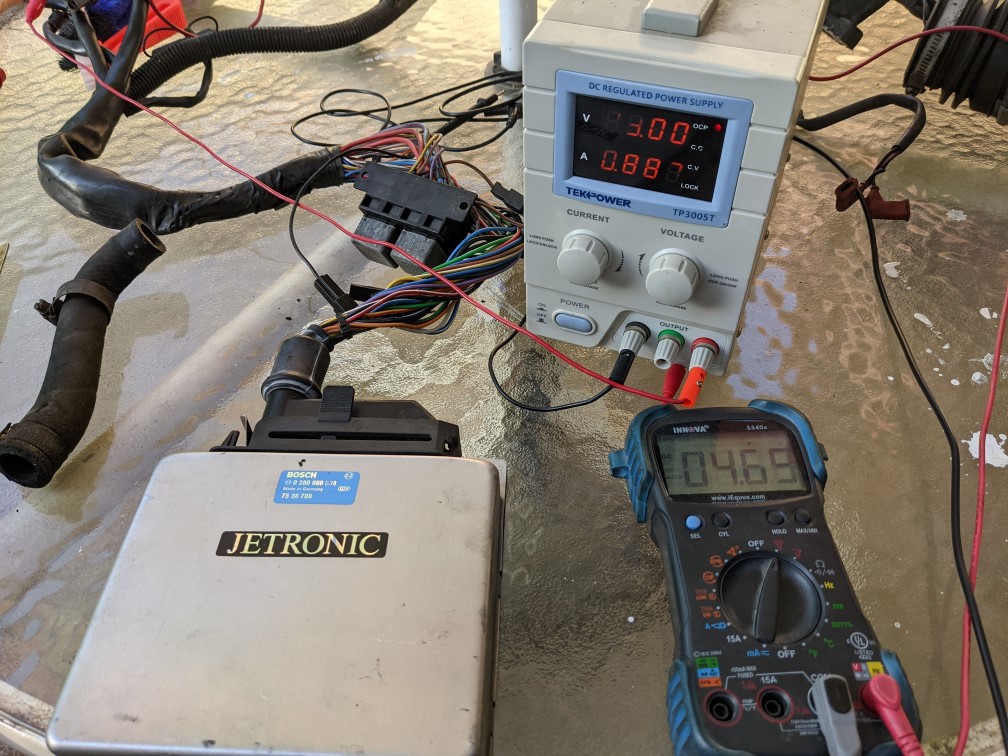

On modern-ish cars, the PWM signal is generated by the ECM in response to ECT. Well, a 900 can't do that. In my mock up, I've used a little PWM signal generator to prove the controller can drive the factory fan quietly. The controller is rated for 60a IIRC, so running both fans isn't an issue... I'm just running one here.

Here's how it looks:

(this video will self destruct in 30 days)

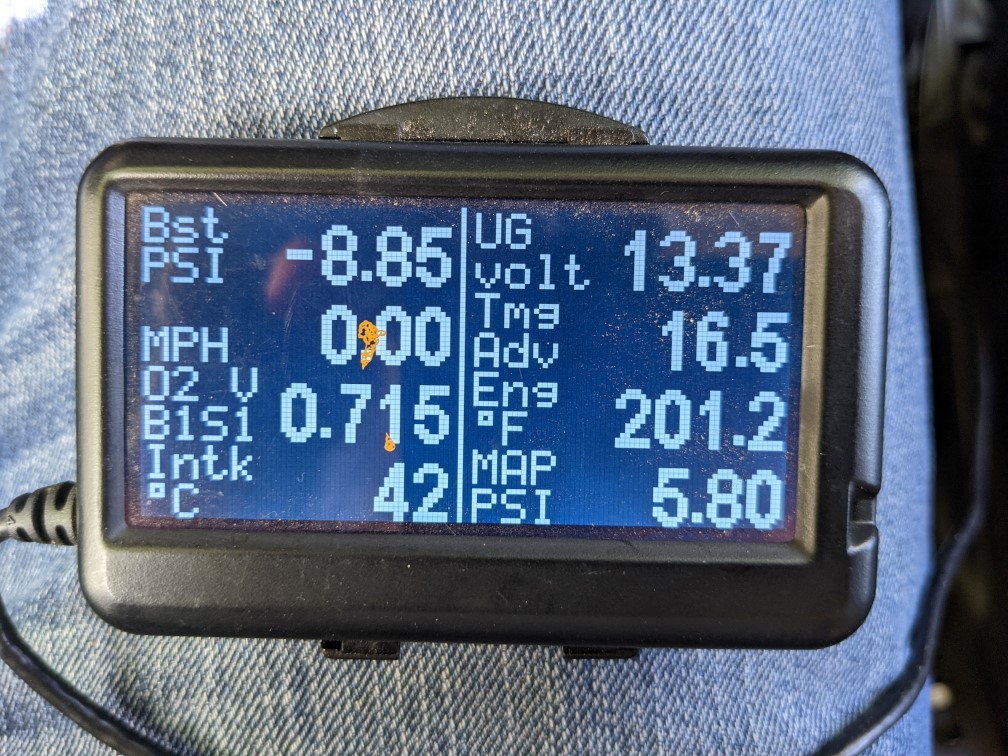

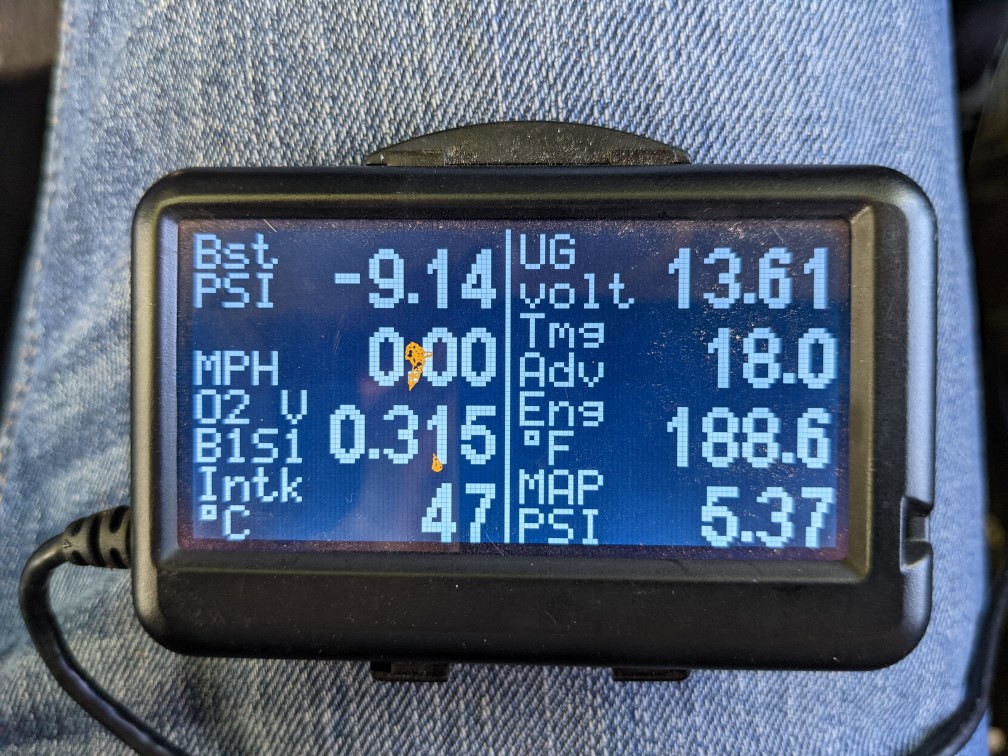

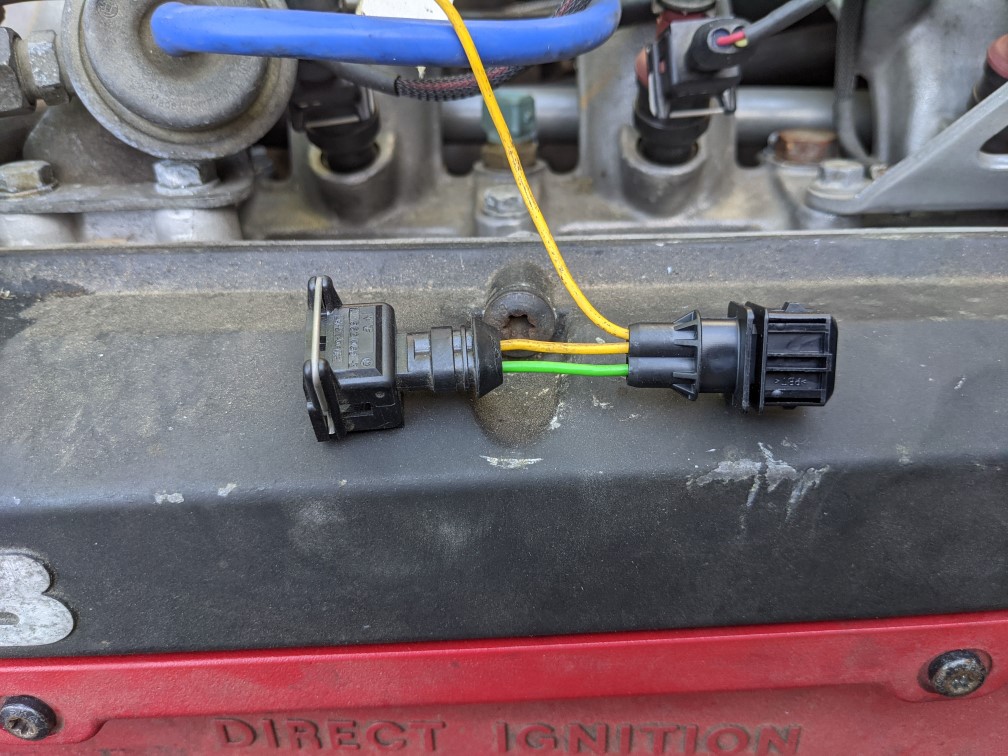

On the Jeep, I used this little doodad:

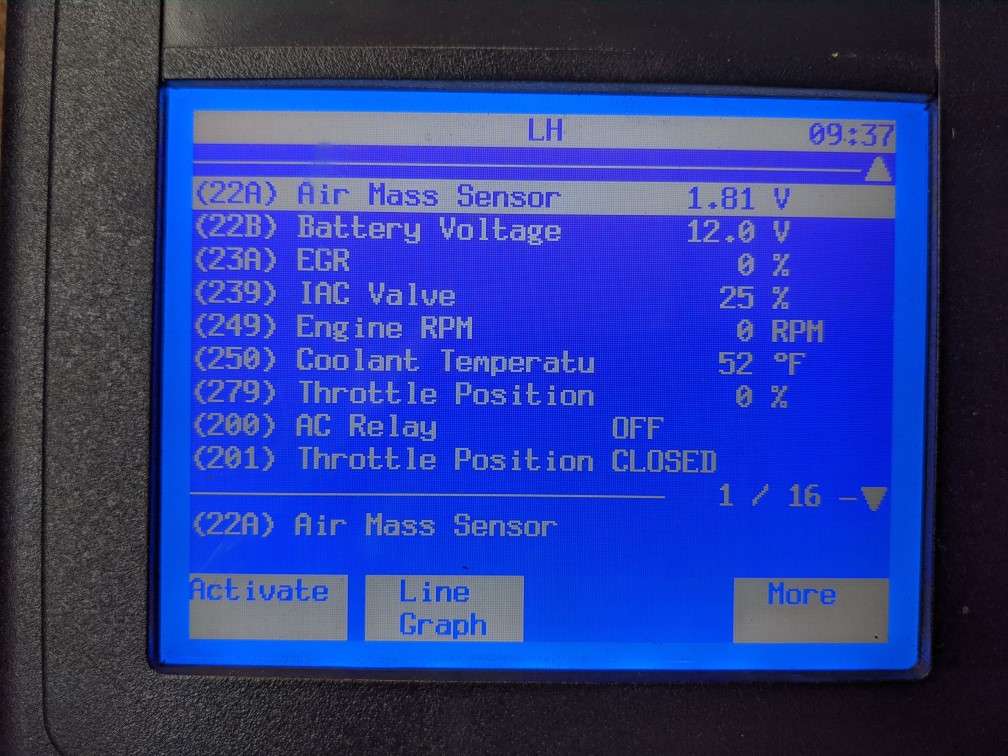

which works a treat. It pilfers the output from the factory ECT sensor and uses the actual engine temp to ramp the fan up as necessary. My plan is to use this device on the 900, too. The concern I have is that the min and max temperature the doodad needs must be separated by .8v (IIRC) and I think operating range of the c900's ECT sensor (like cold engine to very hot engine) is a fairly narrow range. Also, whereas on the Jeep I could use an OBDII scanner to monitor the ECT sensor and ensure my set points were good, that's not an option for the c900. I'm hoping - but don't remember - that Tech 2 can display ECT from LH 2.4.... The alternator is to use an external sensor, maybe also mounted in the intake manifold - but I'm hoping to avoid that.

Wish me luck!

It's been a rip-roaring success, so I'm going to replicate pieces of that project on a c900. Here's most of the parts:

The key bit in that photo is the silver Ford fan controller - part number 6E53-8C609-AA. It's found on later 1st gen Fusions. It's also GM part number 10377609 found on C6 Corvettes. It probably shows up other places, too.

This magic box takes in battery voltage and a PWM signal, and then uses that to modulate power to a DC fan. In concept, it's like the 2-speed fan on the 9000/9-3/9-5 BUT rather than using a resistor to get two speeds it has an infinite number of speeds. (Probably, that's not true - it's probably stepped and just has "a lot" of speeds).

The benefit of using PWM is two-fold: We eliminate high inrush current associated with accelerating a fan from stopped to full speed, which on a c900 should reduce that annoying sag in idle speed when the fans kick in. Also, rather that wait until the engine is "too hot" and then race to cool it down, we can run a fan at low speed relatively early to take the edge off, and accelerate the fan as necessary. In theory, this should result in more stable engine temperatures and reduced load on the electrical system (maybe increase fuel economy a smidge).

On modern-ish cars, the PWM signal is generated by the ECM in response to ECT. Well, a 900 can't do that. In my mock up, I've used a little PWM signal generator to prove the controller can drive the factory fan quietly. The controller is rated for 60a IIRC, so running both fans isn't an issue... I'm just running one here.

Here's how it looks:

(this video will self destruct in 30 days)

On the Jeep, I used this little doodad:

VARIABLE PWM FAN CONTROL works with ANY sensor, compare to Lingenfelter VSFM-002 | eBay

Find many great new & used options and get the best deals for VARIABLE PWM FAN CONTROL works with ANY sensor, compare to Lingenfelter VSFM-002 at the best online prices at eBay! Free shipping for many products!

www.ebay.com

which works a treat. It pilfers the output from the factory ECT sensor and uses the actual engine temp to ramp the fan up as necessary. My plan is to use this device on the 900, too. The concern I have is that the min and max temperature the doodad needs must be separated by .8v (IIRC) and I think operating range of the c900's ECT sensor (like cold engine to very hot engine) is a fairly narrow range. Also, whereas on the Jeep I could use an OBDII scanner to monitor the ECT sensor and ensure my set points were good, that's not an option for the c900. I'm hoping - but don't remember - that Tech 2 can display ECT from LH 2.4.... The alternator is to use an external sensor, maybe also mounted in the intake manifold - but I'm hoping to avoid that.

Wish me luck!