I needed to replace a strut bearing on my 2004 9-3 with 72k miles. Ive owned the car since new, and in the last few months, I noted the strut binding when turning to the right. Ive owned the car since new, and it hasnt gotten a ton of use in the last year or so. Ill also note that I did notice that during cold weather, going over bumps, I was getting a crunching sound which I thought was sway bar bushings, but it was the struts!!!

I replaced mine with Bilsteins, which are more expensive than the OE Sachs and aftermarket KYBs, but are IMO a better design. I replaced front struts as well as rear shocks. Ride is much better, and firm but not harsh as others have defined it.

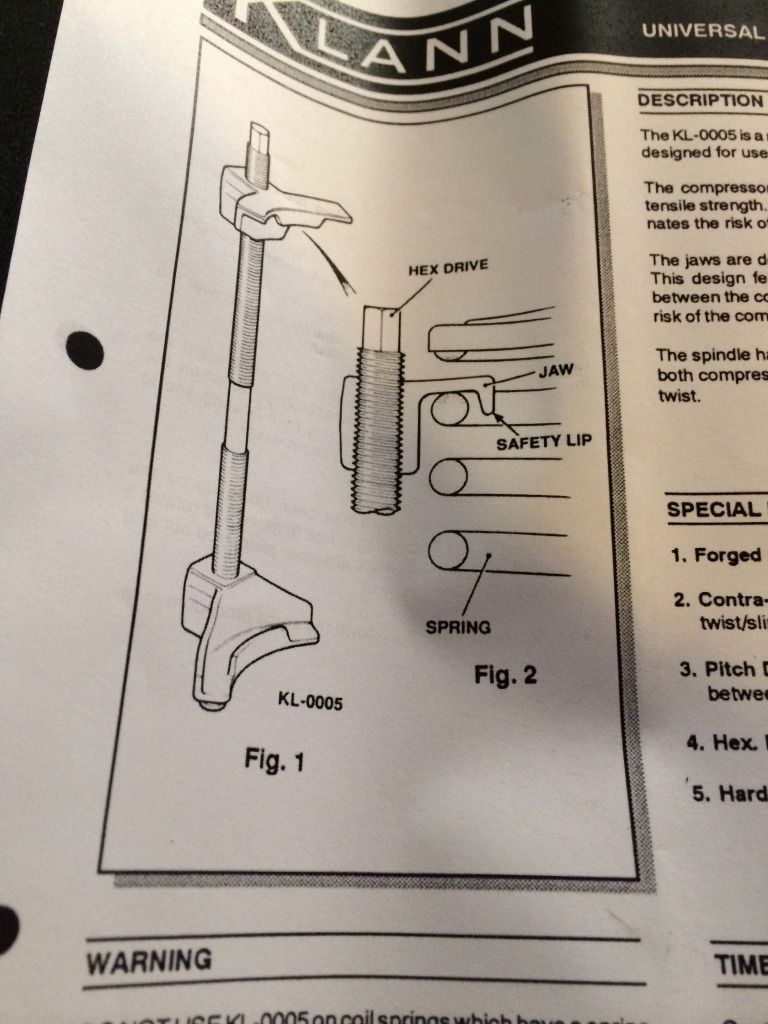

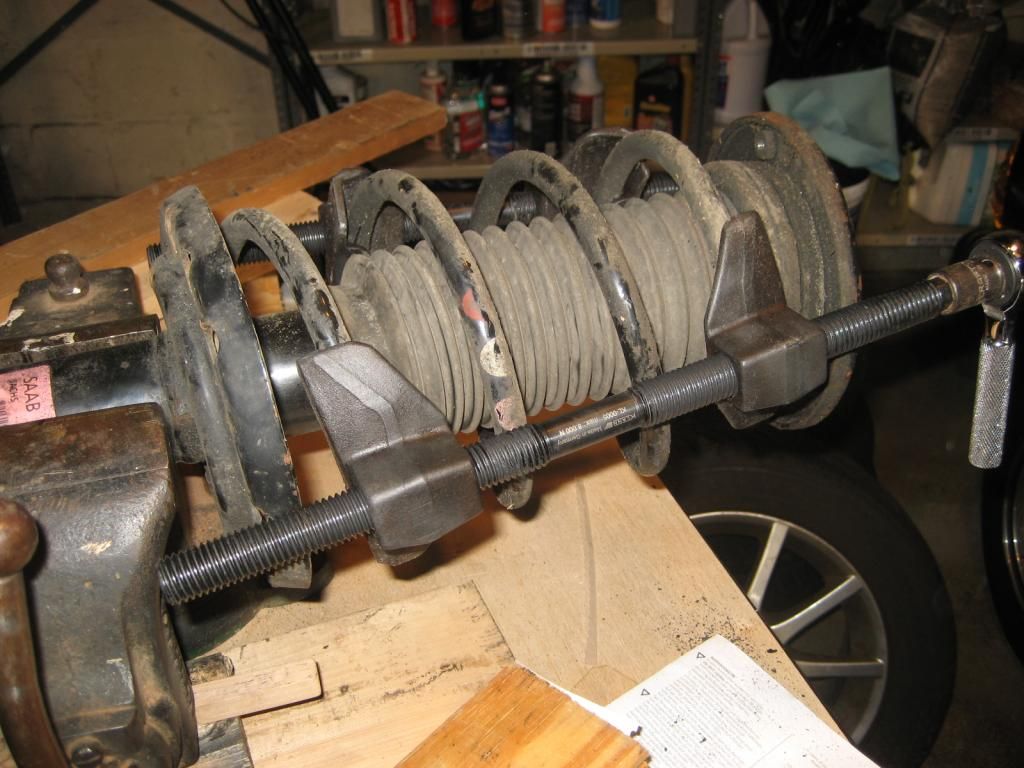

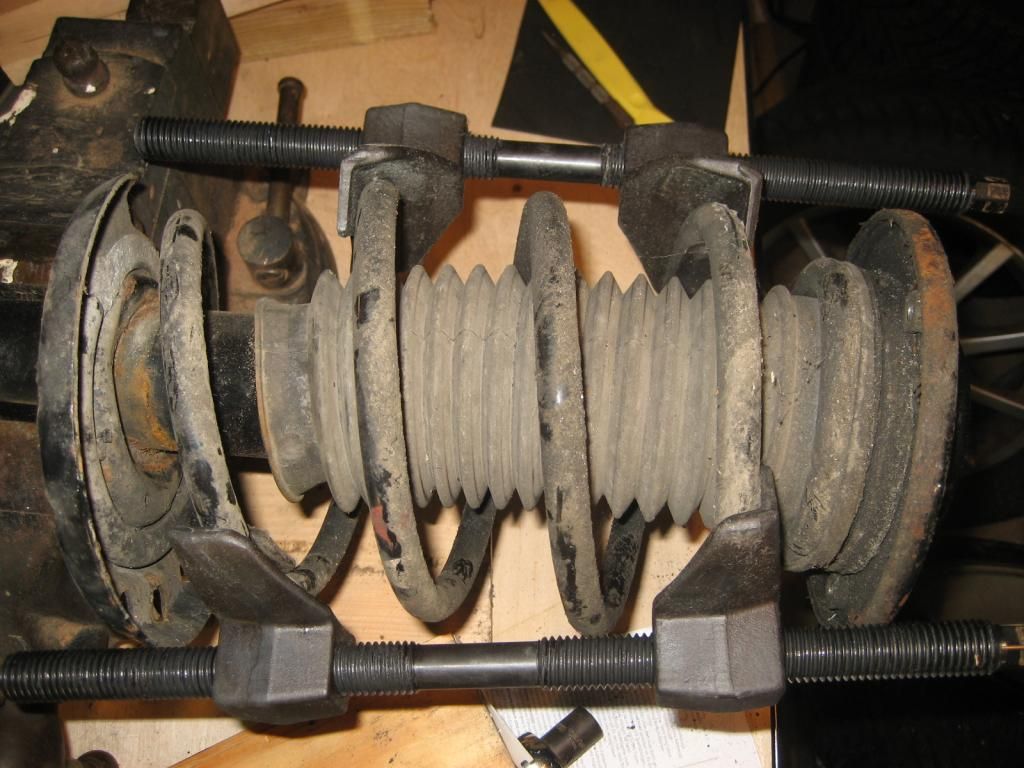

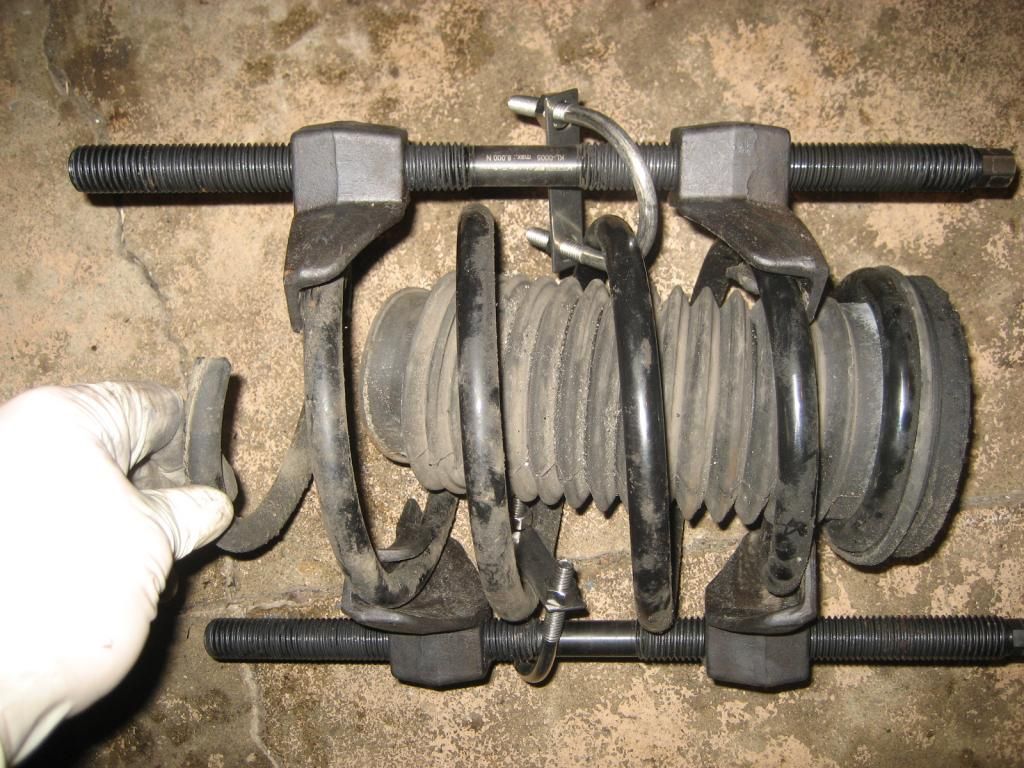

I used a combination of sockets, wrenches, a spring compressor, jack/jackstands, some wood blocks, a flat screwdriver, allen wrenches, female torx sockets, and some Boeshield T-9 and Wurth Film.

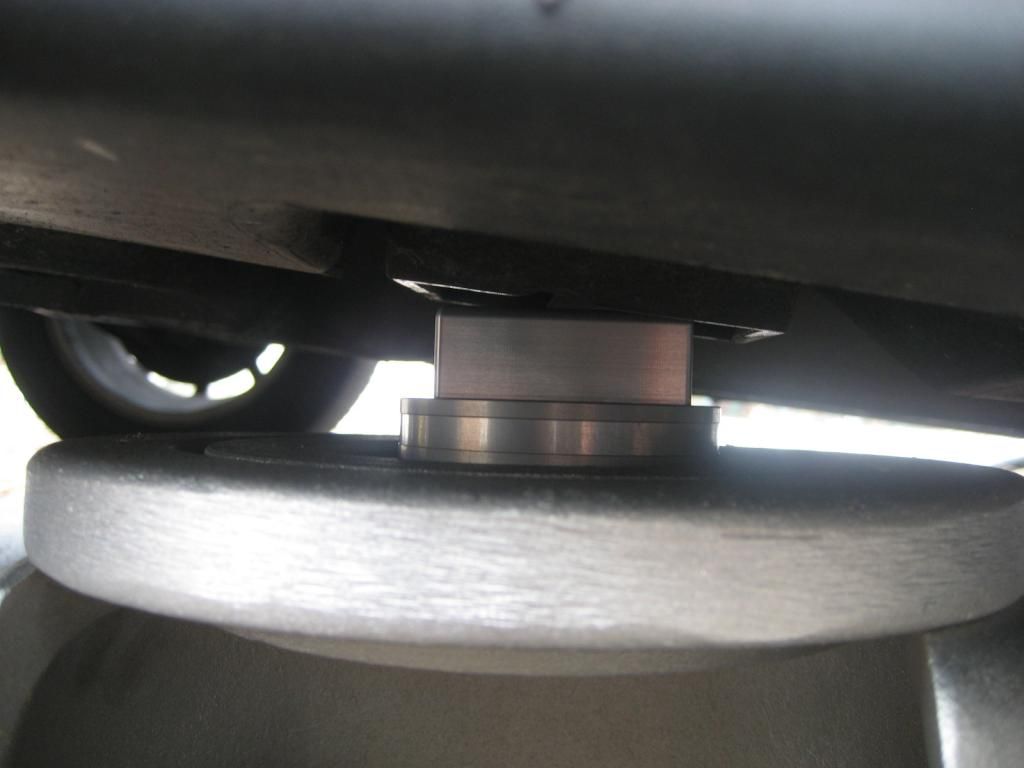

The first step is to suitably support the car. I use jack pads from Reverse Logic and JackPoint Jackstands. I did raise the whole front axle, vs just one side and then the next to get it on the stands, but these pads and stands are more stable and easier to use without causing damage.

![Image]()

![Image]()

![Image]()

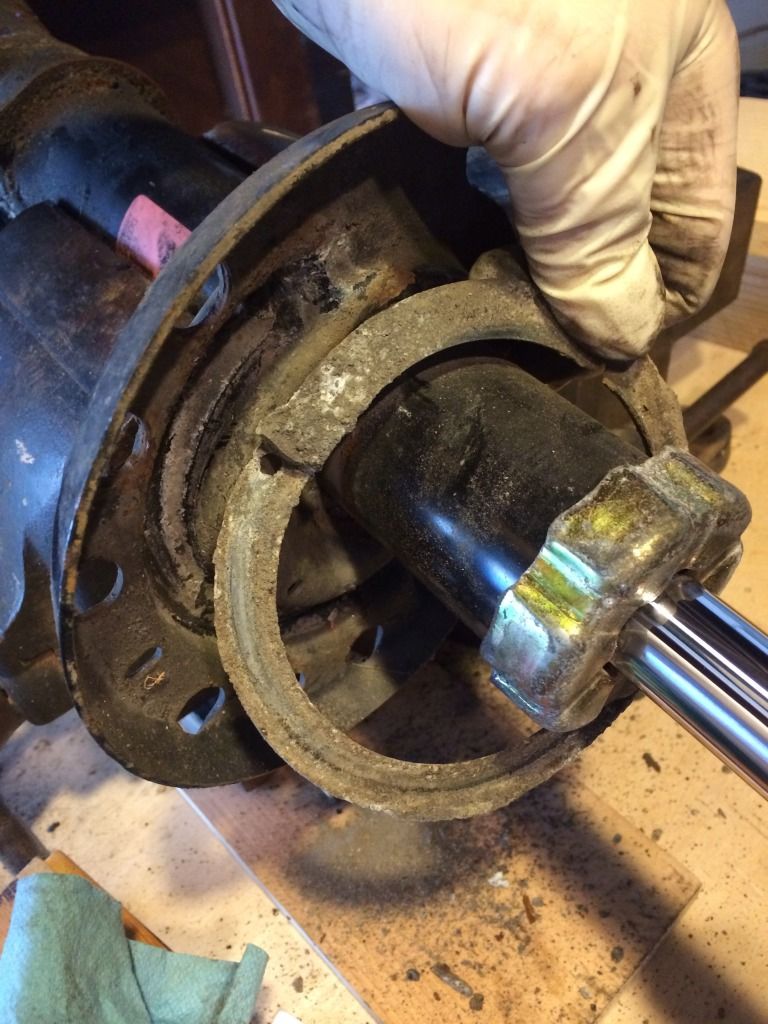

Once up, youll want to support the rotor/steering knuckle for when you remove the strut. I started with some heavy wood but then decided to use a jackstand on the axle.

![Image]()

![Image]()

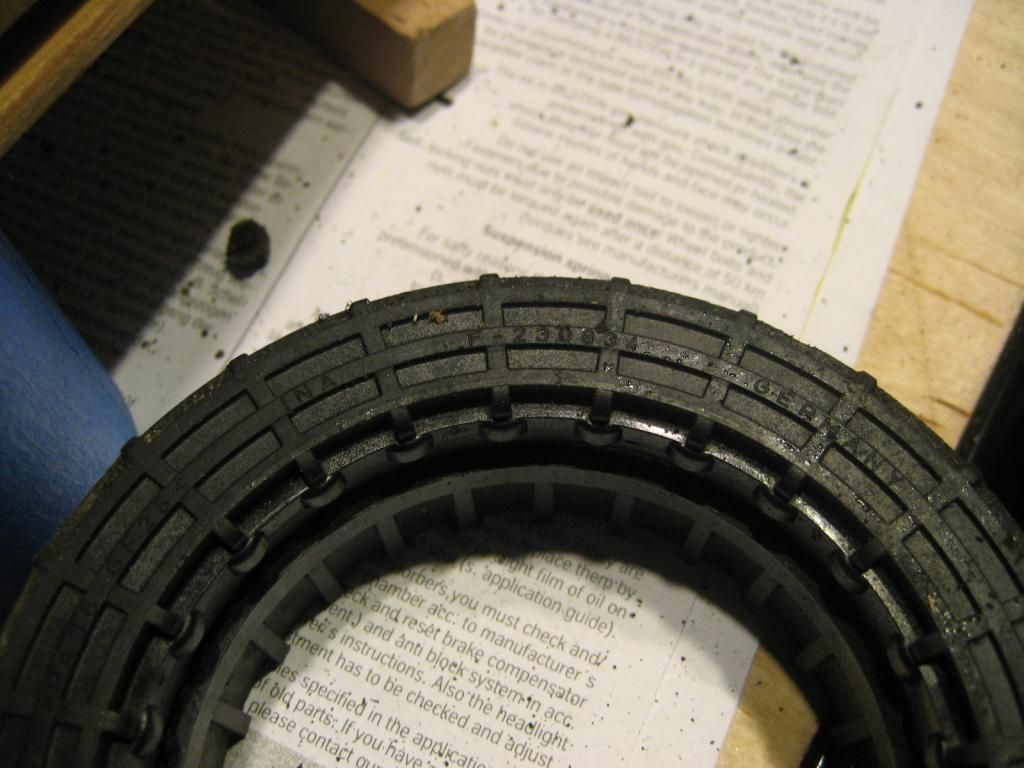

Note that my rotors have always rusted nearly instantly. These are original rotors and pads. Pretty good amount of pad left!

![Image]()

I replaced mine with Bilsteins, which are more expensive than the OE Sachs and aftermarket KYBs, but are IMO a better design. I replaced front struts as well as rear shocks. Ride is much better, and firm but not harsh as others have defined it.

I used a combination of sockets, wrenches, a spring compressor, jack/jackstands, some wood blocks, a flat screwdriver, allen wrenches, female torx sockets, and some Boeshield T-9 and Wurth Film.

The first step is to suitably support the car. I use jack pads from Reverse Logic and JackPoint Jackstands. I did raise the whole front axle, vs just one side and then the next to get it on the stands, but these pads and stands are more stable and easier to use without causing damage.

Once up, youll want to support the rotor/steering knuckle for when you remove the strut. I started with some heavy wood but then decided to use a jackstand on the axle.

Note that my rotors have always rusted nearly instantly. These are original rotors and pads. Pretty good amount of pad left!