CAUTION: Direct access of the motor really is a "last resort" kind of approach to fixing a convertible top. If the control module (computer) figures out that something is out of synch, it will disable the entire convertible operation. This includes the remote trunk button and the button that lowers all 4 windows at once.

This post is meant as a "how I fixed a problem as a DIYer and saved myself some time and money". My computer had already shut down my convertible, so messing with the latching motor wasn't going to do anything detrimental to the soft top.

Given that this is a simple on-off type motor, I won't promise that directly accessing it will shut down the soft top operation, but it's a good bet. To be really safe, I would remove the car's battery first so the control module is really OFF and may not register that something has been changed in the system.

Lastly, please bear in mind that the soft top operation is a complex dance of motors and microswitches, all of which are very precisely controlled by the control module or computer. If the control module notices a deviation or senses a problem, it will probably stop your soft top from moving.

So, be careful.

Work shown below if for a 1996 Saab 900SE 2.0L Turbo convertible

As has been described before, this convertible top is completely inoperable, meaning that pushing the "Roof" switch generates no movement, no motor sound, no nothing. The control module detected that the tonneau motor was removed sometime ago and has shut off all convertible top access.

The roof is closed, and the 5th bow is "locked" in place atop the tonneau cover. The issue at hand is that I need to remove the outer soft top for some restitching and readhere the rear window to the top. But with the 5th bow locked down, there's no way to remove the soft top. What I need is for the motor to unlatch the 5th bow and that's what this addresses.

And before anyone else posts, the emergency manual convertible top release only allows you to raise the roof. It does NOT release the 5th bow latch.

![Image]()

![Image]()

![Image]()

![Image]()

![Image]()

![Image]()

![Image]()

![Image]()

From the WIS with help from John:

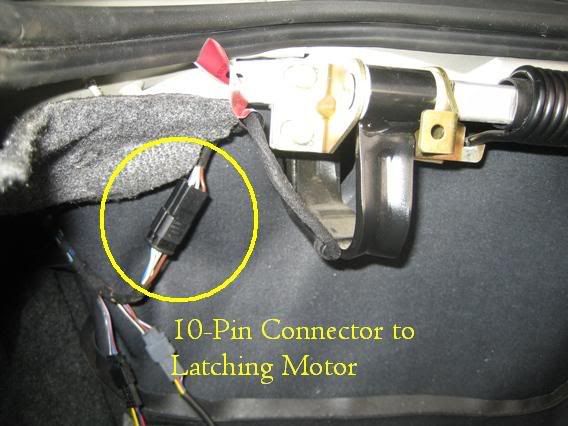

A DC motor opens and closes the latches that lock the fifth bow to the soft top cover. It is located under the cover and is connected to both fifth bow latches via control rods. The latch motor also operates the rotating covers at the front of the cover via torsion wires from the latches. The motor can be run in both directions by reversing the polarity of the motor connections. It is supplied with 12V from the control module when the locks are being operated, from pin 12 (K20) for locking and from pin 2 (K20) when unlocking. If the motor becomes blocked there is a current limiter switch in the control module.A microswitch in the left hand fifth bow latch detects whether the fifth bow is locked or not.

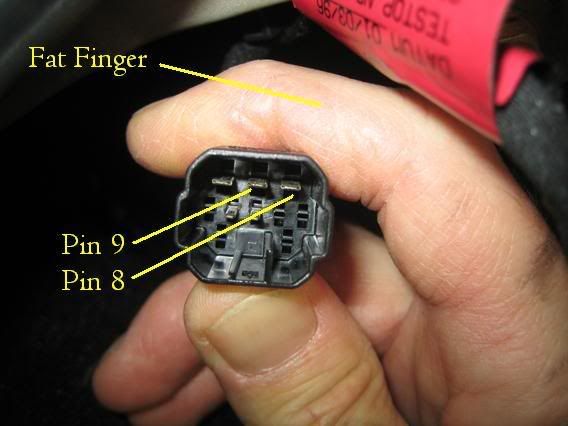

(Power from the TSAS control module goes to connector H10-15 which is a 10 pin connector above left hand wheel housing. Power from pin 2 (unlocking) goes to (8) on the ten pin connector and then to 1 on another connector to the motor).

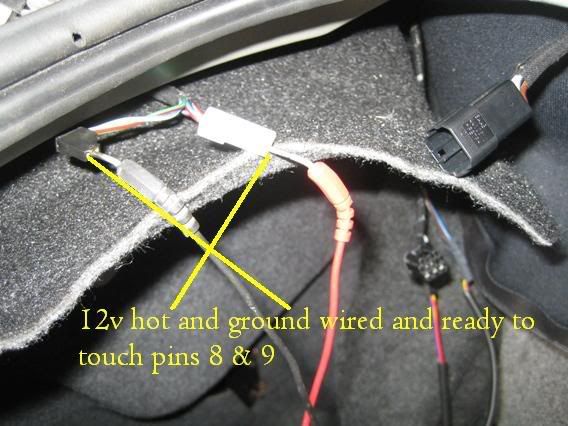

The WIS statement above regarding reversing polarity means that 12v power can be supplied to pin 8 and grounding to pin 9 and will allow the motor to unlatch the 5th bow. 12v power to pin 9 and grounding to pin 8 allows the motor to latch the 5th bow. In my case, 12v power came from the luggage compartment's light.

NOTE: I changed the #4 fuse (interior lights/power antennae) from 7.5A to 10A just for this exercise. The latching motor pulls a good bit of power and blew the 7.5A fuse on the first try.

![Image]()

This post is meant as a "how I fixed a problem as a DIYer and saved myself some time and money". My computer had already shut down my convertible, so messing with the latching motor wasn't going to do anything detrimental to the soft top.

Given that this is a simple on-off type motor, I won't promise that directly accessing it will shut down the soft top operation, but it's a good bet. To be really safe, I would remove the car's battery first so the control module is really OFF and may not register that something has been changed in the system.

Lastly, please bear in mind that the soft top operation is a complex dance of motors and microswitches, all of which are very precisely controlled by the control module or computer. If the control module notices a deviation or senses a problem, it will probably stop your soft top from moving.

So, be careful.

Work shown below if for a 1996 Saab 900SE 2.0L Turbo convertible

As has been described before, this convertible top is completely inoperable, meaning that pushing the "Roof" switch generates no movement, no motor sound, no nothing. The control module detected that the tonneau motor was removed sometime ago and has shut off all convertible top access.

The roof is closed, and the 5th bow is "locked" in place atop the tonneau cover. The issue at hand is that I need to remove the outer soft top for some restitching and readhere the rear window to the top. But with the 5th bow locked down, there's no way to remove the soft top. What I need is for the motor to unlatch the 5th bow and that's what this addresses.

And before anyone else posts, the emergency manual convertible top release only allows you to raise the roof. It does NOT release the 5th bow latch.

From the WIS with help from John:

A DC motor opens and closes the latches that lock the fifth bow to the soft top cover. It is located under the cover and is connected to both fifth bow latches via control rods. The latch motor also operates the rotating covers at the front of the cover via torsion wires from the latches. The motor can be run in both directions by reversing the polarity of the motor connections. It is supplied with 12V from the control module when the locks are being operated, from pin 12 (K20) for locking and from pin 2 (K20) when unlocking. If the motor becomes blocked there is a current limiter switch in the control module.A microswitch in the left hand fifth bow latch detects whether the fifth bow is locked or not.

(Power from the TSAS control module goes to connector H10-15 which is a 10 pin connector above left hand wheel housing. Power from pin 2 (unlocking) goes to (8) on the ten pin connector and then to 1 on another connector to the motor).

The WIS statement above regarding reversing polarity means that 12v power can be supplied to pin 8 and grounding to pin 9 and will allow the motor to unlatch the 5th bow. 12v power to pin 9 and grounding to pin 8 allows the motor to latch the 5th bow. In my case, 12v power came from the luggage compartment's light.

NOTE: I changed the #4 fuse (interior lights/power antennae) from 7.5A to 10A just for this exercise. The latching motor pulls a good bit of power and blew the 7.5A fuse on the first try.