Serpentine Belt How To (DONE!)

Disclaimer - The following describes my experiences with my particular car, a 2004 9-3 linear. YMMV . I am not responsible if you damage your car or yourself by following my example.

. I am not responsible if you damage your car or yourself by following my example.

Safety First - Never crawl under a car supported only by the jack. Safety glasses and mechanics gloves, and the presence of a responsible adult are always a wise idea. :nono;

Replacement Interval According to the service booklet that came with my car, belt replacement is recommended every 60,000 miles. Since I have no evidence that the previous owner got the belt replaced, I decided to do it myself at 80K.

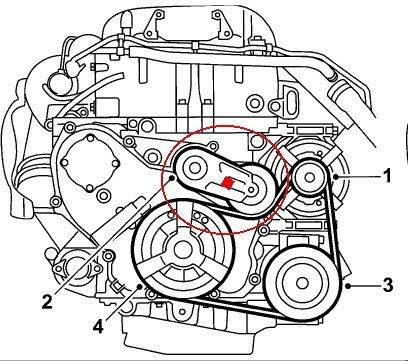

The picture below will get you oriented, I've circled the tensioner. It's spring loaded and helps to take up the slack in the belt. This makes belt changes much easier (in theory) than they were when alternators and the like had to be moved on their brackets to adjust the tension.

The tensioner can be moved by putting a tool with a 3/8" square drive into a hole (red square) in the tensioner and moving the tool up. Unfortunately, you'll need to learn to do this without being able to see the hole very well :roll:

![Image]()

The first step is to buy the tool, it looks like this:

![Image]()

Unfortunately, the tool I bought was too long fit, either from above or below. One problem is that the 3/8" square protrusion is fixed. It's the same size as the one on a ratchet, but unlike a ratchet it doesn't move, making it difficult to find a position under the hood (or below) that would tolerate such a long tool. A ratchet or breaker bar are too wide to fit between the tensioner and the fender

The solution:

![Image]()

I mangled the bar - I cut off several inches and bent what was left - you'll see why eventually. There must be a better/different tool, but I was impatient.

I wound up doing the job twice because the new belt I had on hand was too small :evil: (see below). The first time I put the car safely on jack stands and removed the wheel. This lets you remove the two circled bolts.

![Image]()

The fender liner is moved aside, permitting you to see the lower pulleys clearly. You might need to remove a couple more nuts, depending, but you don't need to remove the entire fender liner. It turns out that removing the wheel is NOT necessary, you have perfectly good access from below if you put the car safely on ramps, instead.

I used ramps and wheel chocks the second time, and it was much easier.

Disclaimer - The following describes my experiences with my particular car, a 2004 9-3 linear. YMMV

Safety First - Never crawl under a car supported only by the jack. Safety glasses and mechanics gloves, and the presence of a responsible adult are always a wise idea. :nono;

Replacement Interval According to the service booklet that came with my car, belt replacement is recommended every 60,000 miles. Since I have no evidence that the previous owner got the belt replaced, I decided to do it myself at 80K.

The picture below will get you oriented, I've circled the tensioner. It's spring loaded and helps to take up the slack in the belt. This makes belt changes much easier (in theory) than they were when alternators and the like had to be moved on their brackets to adjust the tension.

The tensioner can be moved by putting a tool with a 3/8" square drive into a hole (red square) in the tensioner and moving the tool up. Unfortunately, you'll need to learn to do this without being able to see the hole very well :roll:

The first step is to buy the tool, it looks like this:

Unfortunately, the tool I bought was too long fit, either from above or below. One problem is that the 3/8" square protrusion is fixed. It's the same size as the one on a ratchet, but unlike a ratchet it doesn't move, making it difficult to find a position under the hood (or below) that would tolerate such a long tool. A ratchet or breaker bar are too wide to fit between the tensioner and the fender

The solution:

I mangled the bar - I cut off several inches and bent what was left - you'll see why eventually. There must be a better/different tool, but I was impatient.

I wound up doing the job twice because the new belt I had on hand was too small :evil: (see below). The first time I put the car safely on jack stands and removed the wheel. This lets you remove the two circled bolts.

The fender liner is moved aside, permitting you to see the lower pulleys clearly. You might need to remove a couple more nuts, depending, but you don't need to remove the entire fender liner. It turns out that removing the wheel is NOT necessary, you have perfectly good access from below if you put the car safely on ramps, instead.

I used ramps and wheel chocks the second time, and it was much easier.